1. Corrosion Resistance:

One of the primary advantages of stainless steel tubes is their exceptional resistance to corrosion. The chromium content in stainless steel forms a passive oxide layer on the surface, which acts as a protective barrier against corrosive elements. This makes stainless steel tubes highly resistant to rust, oxidation, and chemical corrosion, even in harsh environments. Consequently, they have a longer lifespan and require less maintenance compared to other materials.

2. Strength and Durability:

Stainless steel tubes are known for their superior strength and durability. They exhibit high tensile strength and can withstand heavy loads and extreme temperatures. This makes them ideal for applications where structural integrity is crucial, such as construction, automotive, and aerospace industries. Stainless steel tubes also maintain their strength over a wide range of temperatures, making them suitable for both hot and cold environments.

3. Hygiene and Sanitation:

Stainless steel tubes are widely used in industries that require strict hygiene and sanitation standards, such as food processing, pharmaceuticals, and healthcare. The smooth, non-porous surface of stainless steel prevents the accumulation of bacteria, dirt, and contaminants, making it easy to clean and sanitize. Additionally, stainless steel is non-toxic and does not leach harmful chemicals into the substances it transports, ensuring product purity and safety.

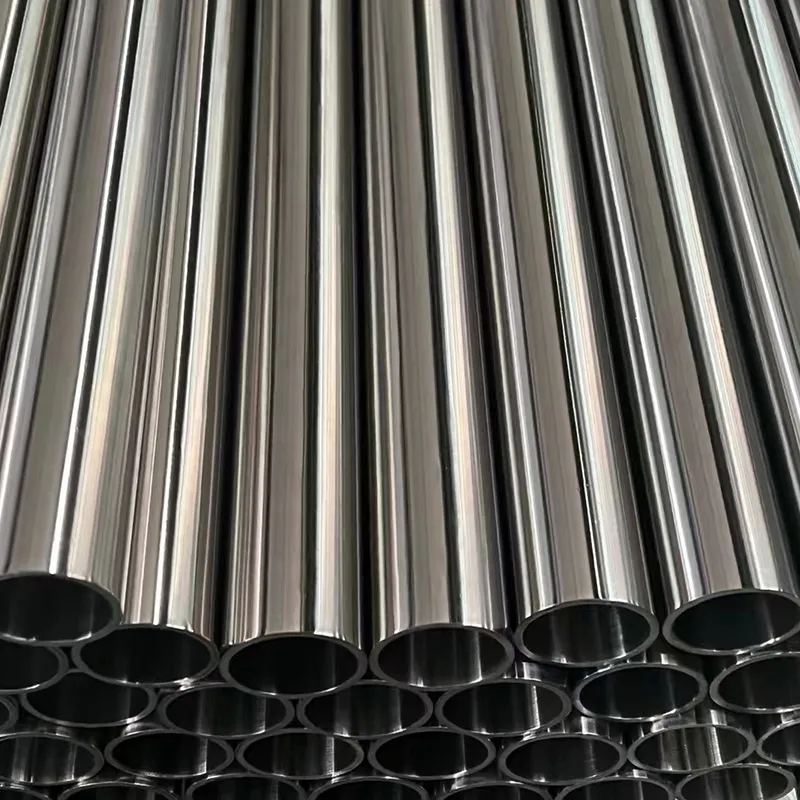

4. Aesthetic Appeal:

In addition to their functional advantages, stainless steel tubes offer aesthetic appeal. The sleek, polished surface of stainless steel enhances the visual appeal of architectural structures, interior designs, and decorative applications. Stainless steel tubes are available in various shapes, sizes, and finishes, providing designers and architects with a wide range of options to create visually appealing and modern designs.

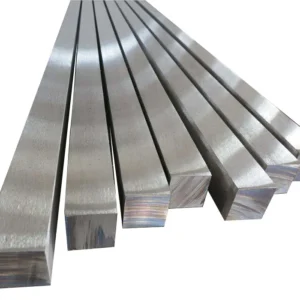

5. Versatility:

Stainless steel tubes are highly versatile and can be customized to meet specific requirements. They can be easily fabricated, welded, and formed into various shapes, including round, square, rectangular, and oval. This versatility allows for the design and manufacture of complex structures, pipelines, heat exchangers, and other components in different industries. Stainless steel tubes also offer compatibility with a wide range of fittings and connectors, further enhancing their versatility.

6. Sustainability:

Stainless steel is a highly sustainable material. It is 100% recyclable, and its scrap value makes it economically viable to recycle. Recycling stainless steel reduces the demand for virgin materials, conserves natural resources, and minimizes waste generation. Furthermore, stainless steel’s long lifespan and low maintenance requirements contribute to its environmental sustainability.

7. Fire and Heat Resistance:

Stainless steel tubes exhibit excellent fire and heat resistance properties. They have a high melting point and do not release toxic fumes when exposed to high temperatures. This makes them suitable for applications that require fire resistance, such as building construction, transportation, and industrial equipment.

Conclusion:

Stainless steel tubes offer numerous advantages, including corrosion resistance, strength and durability, hygiene and sanitation, aesthetic appeal, versatility, sustainability, and fire and heat resistance. These qualities make stainless steel tubes a preferred choice in a wide range of industries, including construction, automotive, food processing, healthcare, and more. As technology and manufacturing processes continue to advance, stainless steel tubes are likely to play an increasingly vital role in various applications, contributing to the overall progress and development of different sectors.